Does your ecommerce business suffer from frequent stockouts, backorders, delayed shipments, or customer complaints about late deliveries? If so, you have a supply chain problem. It’s important to identify and fix supply chain problems quickly, because they cause bigger, revenue-affecting problems down the line with canceled orders and declining customer conversion, retention, and lifetime value as they decide to shop elsewhere.

To identify problem areas, you’ll need to take a closer look at all the steps that go into manufacturing, stocking, order fulfillment, and delivering products to your customers. Somewhere in that ecommerce supply chain you are falling short, failing to meet deadlines, or setting unrealistic expectations. But where?

Lead times are the key to understanding inventory management. In most cases, reducing lead times gives you more control over your inventory, resulting in faster, on-time delivery for your customers. Let’s take a look at the different types of lead times in your supply chain and see where you might need help.

What is Lead Time?

Lead time is the timeI . There may be several different types of lead times that affect your ecommerce business, depending on whether or not you manufacture your own branded goods or sell multiple brands as an online retailer.

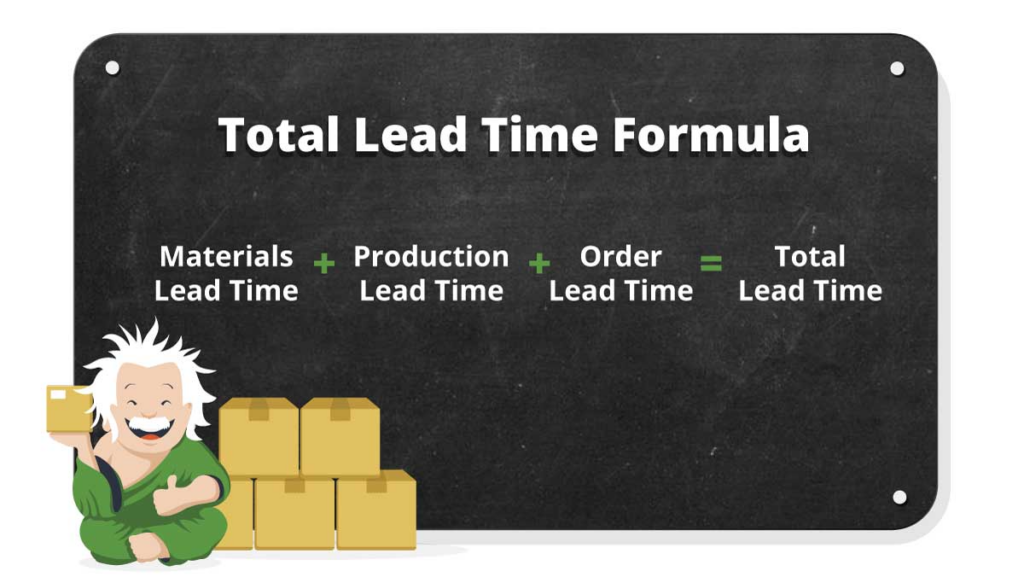

Materials Lead Time — the time it takes for the factory to receive raw materials from supplier(s).

Production Lead Time — the time it takes to manufacture your product and have it delivered to your warehouse or fulfillment center.

Order Lead Time — the time it takes for a customer’s order to be processed, shipped, and delivered to their address.

Lead Time Formula

To calculate total lead time, simply add up all the components: materials order time, production time, and order lead time.

5 Benefits of Shorter Lead Times

1. If you can shorten your materials order time and production time, you can keep smaller quantities of materials and finished goods on hand, and pay less in holding/carrying costs. But be aware that by ordering more frequently, you’ll incur higher receiving and restocking costs. There is a formula for calculating your ideal economic order quantity (EOQ) which can help determine when and how much to order.

2. Holding less inventory and ordering in smaller quantities means you’ll have more cash on hand to use on other projects.

3. You can replenish inventory faster to reduce stockouts and backorders.

4. Your business will be more agile and better able to react to changes in the market or seasonal ups and downs.

5. Faster delivery times can differentiate your business from your competitors.

Troubleshooting Long Lead Times

When troubleshooting lead time issues, first identify the problem, then test different solutions. You will need the cooperation of suppliers, manufacturers, third-party logistics (3PL) or fulfillment providers, shipping companies, and other outside vendors, over which you have very little control. If one of these partners refuses to work with you or cannot solve your problem, the first option would be to find a partner that will work with you. If, ultimately, you can’t reduce lead time, you can at least anticipate and prepare for it.

Problem: Production Delays

Solution: If your manufacturing process is subject to long delays while waiting for supplies, consider ordering larger quantities at a time, changing shipping methods to receive materials faster, or buying local to reduce shipping time and costs.

Problem: Stockouts

Solution: Stockouts are a leading cause of customer complaints and late deliveries. Today’s advanced inventory management systems help prevent stockouts by giving you access to real-time inventory levels, helping you track and manage inventory across multiple warehouses, and automating reports, reorder points, and notifications.

Problem: Fulfillment Errors and Delays

Solution: Work with your fulfillment center or 3PL to identify the cause of the problem and potential solutions. Give them plenty of lead time to prepare for promotions or peak sales periods. Avoid stockouts, which cause delays. If your fulfillment provider consistently fails to keep up with orders and refuses to address problems, it’s time to find a new partner. ShipMonk’s focus on technology and automation optimizes the fulfillment process for speed and accuracy while giving ecommerce businesses a powerful, easy-to-use system for tracking and managing inventory.

Problem: Shipping delays

Solution: You can’t control traffic or the weather, but you can avoid both by not handcuffing your business to a single shipping carrier for incoming freight shipping or outgoing orders. A 3PL that ships thousands of packages per day and partners with all major global, national, and local shipping carriers has superior options and much more data to work with when forwarding freight or routing orders for delivery.

Problem: Lengthy Production Process

Solution: Work with your supplier(s) to reduce bottlenecks and inefficiencies. Perhaps some of the more time-consuming components can be pre-assembled by suppliers. Perhaps smaller but more frequent orders would be easier for the factory to handle. Look for redundancies and unnecessary steps to optimize the process.

Problem: Missed Deadlines

Solution: Hold suppliers and shipping companies accountable for missing promised timeframes, unexpected price changes, and damaged goods. Make sure your contract stipulates the delivery timeframe, and what actions will be taken if the deadline is missed or goods are not delivered as promised. Ask for advance notice of stock shortages and offer incentives to suppliers who meet or beat those timelines.

How a 3PL can Help

3PLs are experts in efficiency and logistics. They can help you get orders out the door faster, help you save on shipping, and help you manage your inventory more easily.

Automation and Robotics — ShipMonk’s state-of-the-art fulfillment centers are built for efficiency from the ground up, taking advantage of automation and robotics wherever it makes sense to create efficiencies and reduce errors. Orders placed by 10 a.m. are shipped out that same day, and most within 24 hours. Our commitment to ongoing process improvements means you can take advantage of the best the industry has to offer without having to worry about it as your business grows.

Powerful Order, Inventory, and Warehouse Management Systems — ShipMonk’s advanced 3PL fulfillment software platform is an all-in-one order, inventory, and warehouse management system. Seamless technology integrations give you 24/7/365 transparency into the entire post-purchase process. Orders coming from multiple sales channels can be prioritized and routed, while inventory distributed across multiple fulfillment centers can be tracked and managed in real time.

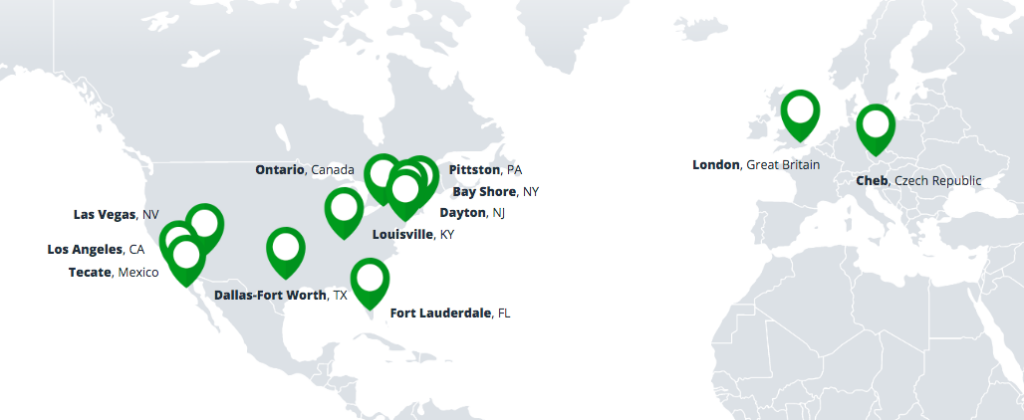

Multiple Warehouse Locations — ShipMonk employs 2,000+ team members across 12 state-of-the-art facilities in the US, Canada, Mexico, and Europe. By distributing inventory across multiple warehouse locations, ecommerce brands can shorten shipping distances, reduce costs, and offer their customers 2-day delivery to virtually any location in the U.S.

Shipping Network — ShipMonk’s first-of-its-kind, carrier-agnostic Virtual Carrier Network automatically routes each order the most efficient way, based on its size, weight, destination, speed, carrier capacity and performance. We can also help with incoming freight, whether domestic or international.

As America’s fastest-growing third-party logistics provider for direct fulfillment, B2B, and retail fulfillment, ShipMonk’s commitment to technology and automation reduces lead times every day. And the faster we work, the faster your ecommerce brand can grow! Contact us for a quote today.