Everyone has heard the terms SKU, UPC, and barcode, but most of us have never understood the subtle differences between them. As a result, many people use these terms interchangeably or incorrectly, adding to the confusion.

SKUs, UPCs, and barcodes do have one thing in common: they’re all codes used to identify and track things. Each is used in different ways, for different reasons. If you’re in the business of manufacturing or purchasing products, and fulfilling and shipping orders, these distinctions become pretty important. So, it’s time we cleared things up! We’ll give you the definitions for SKU, UPC, and barcode, and cover their differences and how each is used.

What is a SKU?

SKU stands for Stock Keeping Unit. It’s a unique code created and used internally by retailers and ecommerce sellers to identify each unique product and product variation that they sell. A SKU can use letters, numbers, and symbols and be as short or long as necessary to differentiate one product from another. The code might include details on the product, including style numbers, size, color, weight, price, expiration date, and more. It might be an easily decipherable code, like WM-TS-BLK-LG, or a series of letters and numbers indecipherable to anyone who works outside the company.

Since SKUs are typically for internal tracking purposes, they can be customized to your needs and changed when necessary. You don’t usually have to worry if they’re the same as a SKU from another company. In cases where you’re working with 3rd parties that have products from several companies, such as retailers, 3PLs, or fulfillment centers, you may need to add a barcode, more on that in a bit, to ensure that they can distinguish your products from others. Learn more about SKUs.

What is a Barcode?

A barcode is a method of representing data in a visual, machine-readable form. Unlike a SKU, barcodes are used externally by all the businesses in the retail supply chain, including wholesalers, retailers, and resellers. Traditionally, barcodes represented data by varying the widths and spacings of parallel lines. Recently, some variants utilize rectangles, dots, hexagons, and other patterns.

When scanned by a barcode reader, the barcode reveals the data encoded. Barcodes are used to quickly convey a lot of information in a small space. The larger the barcode, the more information it can store.

There are many barcode formats, called symbologies, with as many as 30 different types developed for specific industries. The two main types of barcode symbologies:

One-dimensional barcodes, also called linear barcodes. One-dimensional barcodes can be broken down further into:

One-dimensional numeric barcodes, consisting of bars and numbers, are the most common type of barcode. The 12-digit UPC or Universal Product Code (more information to come) is the barcode you’ll generally see on products in North America. Manufacturers outside North America use a 13-digit barcode called an EAN (European Article Number) or IAN (International Article Number). Other numeric barcodes of varying lengths have been standardized for specific industries, such as POSTNET, used by the US Postal Service.

One-dimensional alpha-numeric barcodes consist of bars, letters, and numbers and are, therefore, capable of encoding more information. They’re used in grocery stores, libraries, automotive and defense industries, among others.

Two-dimensional barcodes are square or rectangular-shaped images made up of cells filled with dots. They do not contain visible letters and numbers. These types of barcodes can encode thousands of characters. The most common example of a 2D barcode is a QR code. You also probably have a 2D barcode on the back of your driver’s license. Datamatrix barcodes are tiny 2D barcodes often used on small electronic components.

Barcodes are used thousands of ways by all different types of businesses, not just retail, and new barcode technologies are being developed all the time. The type of barcode used depends on the industry, the amount of information it needs to contain, and the amount of space available to print it. Some examples of different barcodes are below:

Barcodes Used in Ecommerce and Retail

In the ecommerce/retail supply chain, most barcodes are the linear, one-dimensional numeric variety. They’re used mainly for two purposes: product barcodes and shipping barcodes.

Product Barcodes

Large brands that sell products through multiple marketplaces and retailers are required to register their products with UPCs or EAN/IAN barcodes, depending on where they’re manufactured. Smaller direct-to-consumer (DTC) brands and private label brands don’t need registered UPCs for their one-of-a-kind products — at least not right away. These smaller brands may use different types of barcodes internally, however, to quickly identify their products for storage, fulfillment, and returns. Larger and more advanced 3PLs and fulfillment providers are starting to require barcodes on products to ensure accuracy when receiving, slotting, fulfilling, and shipping orders. These requirements help drive better efficiencies and help keep your operational costs down. These barcodes do not, however, need to be purchased as GS1-assigned UPCs.

Alternatively, smaller ecommerce businesses can use any barcode supplier, such as their storefront system or 3PL fulfillment software, to create simple but unique barcodes for each SKU. Since they’re only used internally for fulfillment and returns, there is little danger of them being mixed up with other products. Just make sure your fulfillment center supports the type of barcode you choose. ShipMonk, for example, supports a wide variety of 1D and 2D barcodes, including UPC/EAN versions UPC-A, UPC-E, EAN-8, EAN-13, Code 128-A, Code 128-B, Code 128-C, GS1-128, Code 39, ASIN, FNSKU, and QR codes.

Shipping Barcodes

Shipping carriers, including UPS, FedEx and USPS, have their own standardized barcode formats, usually numeric or alphanumeric barcodes. Data encoded on a shipping barcode usually includes the package’s origin, destination address, weight, shipping carrier and shipping class (Ground, Priority Mail, Next Day Air, etc.). Freight companies shipping in bulk also use shipping barcodes, which may include additional information helpful with inbound receiving.

DTC ecommerce businesses must first select a shipping carrier and input the customer’s address before printing out a shipping label with a machine-readable shipping barcode. This process is automated at advanced fulfillment centers that ship thousands of packages a day. The shipping label is applied to the outside of the box or bag. The barcode is scanned when loaded onto the shipping carrier’s truck, and every time it is moved or changes location on its way to the customer’s home. Packages can be tracked by the 3PL, the ecommerce seller, and the customer by means of the shipping barcode.

What is a UPC?

UPC, or Universal Product Code, is a 12-digit barcode symbology often used synonymously with Global Trade Item Numbers (GTINs), as the GTIN is typically the code used to generate a UPC barcode. GTINs are unique identification numbers available for purchase from GS1. This international, non-profit organization generates and sells these unique identifiers for use by brands in the US & Canada. Once assigned to a product, a GTIN stays with that product for life and can never be reused; GS1 keeps a database of all GTINs issued, which can be used to verify product authenticity.

To create UPC barcodes, brands can purchase GTIN’s individually for a small number of products, or in bulk for thousands of products. For bulk purchases, the brand is assigned a unique company prefix, which then becomes the first several digits on each GTIN they purchase; the remaining digits are the item number and a check digit, which serves to verify that all the numbers have been entered correctly when the barcode is scanned. Once the brand has its GTIN numbers, they link one to each product by entering numbers in its POS or inventory management systems (IMS). The barcode art can be outsourced to any barcode printer. Ecommerce platforms such as Shopify and Square can produce UPC barcodes from GTINs, as can full-service 3PLs like ShipMonk. You can also ask your manufacturer or supplier to print the UPCs directly on your packaging or hang tags.

The standardized use of GTINs in UPCs is to ensure “universal” compatibility with scanning machines used in receiving and storage at warehouses, by third party logistics providers for ecommerce order fulfillment and returns, and at retail point of sale. Because GTINs in UPCs are unique to a specific product, they can be used in online searches to locate an authentic, branded product among dozens of knockoffs. They’re also required by most major retailers and marketplaces, including Amazon, Walmart and Target, to verify a product’s authenticity and ensure compatibility with their scanning systems.

Unlike SKUs, GTINs/UPCs do not encode detailed product information such as price or color. They simply identify the manufacturer and the product or item number. Specific details about the product are stored in the retailer’s POS system. When the UPC is scanned at POS, the system calls up all the details based on the item number, including the price. This enables retailers to set their own price for each item. In most cases, retailers and ecommerce sellers assign both a SKU and a UPC to the same product, in order to track sales and manage inventory both internally and externally.

One last note about UPCs. Since the C stands for code, calling it a UPC code is redundant. You can refer to the GTIN as a UPC number, or the barcode portion as a UPC barcode, but those in the know will never call it a UPC code. It is simply a UPC.

So, Which Codes Should Your Ecommerce Business Use?

It depends. While smaller ecommerce brands can get by with a simple SKU on each product, as you add more and more SKUs to your assortment, you may want to add simple, self-generated barcodes to make inventory easier to manage internally.

Once your ecommerce business reaches a point where you can no longer keep up with fulfillment, partnering with a 3PL can streamline operations and help your business grow even faster. At this point, you may be required by the 3PL to have some type of barcode on all your products. There are no size or format restrictions, other than that it must fit somewhere on the product package or hangtag.

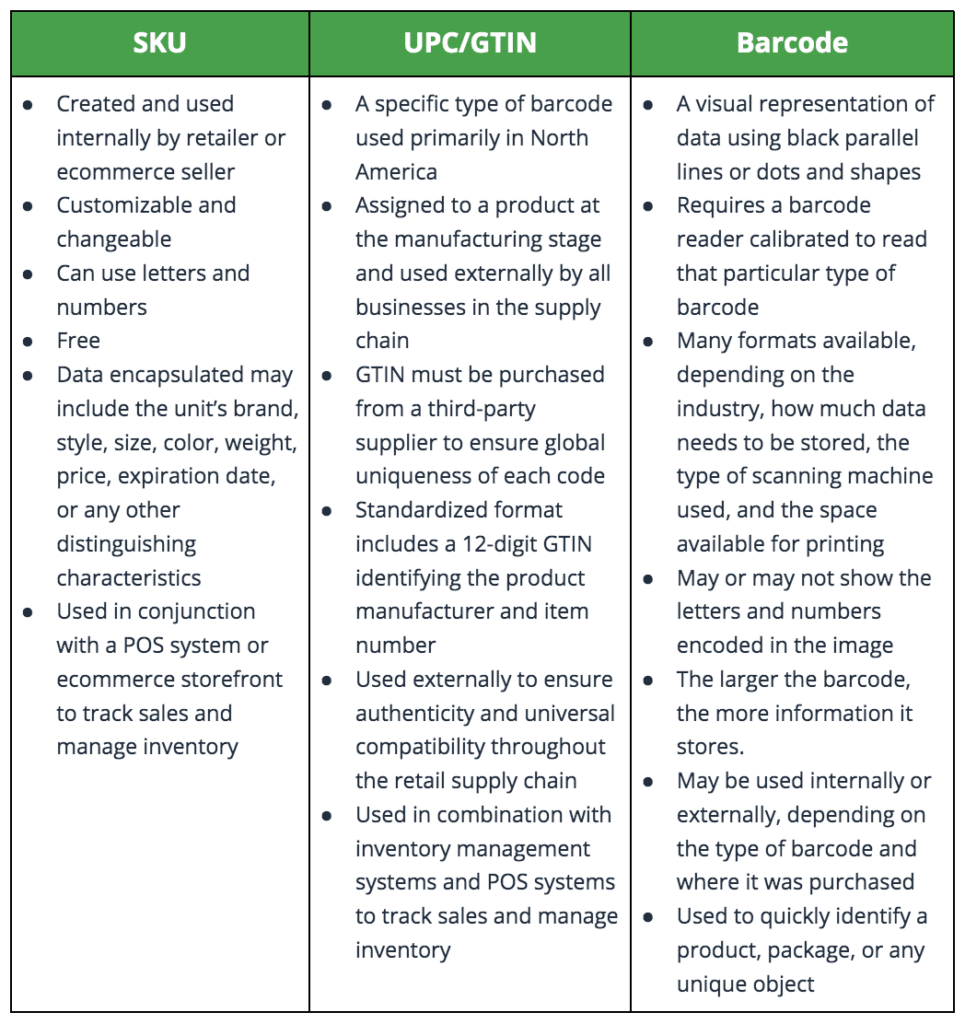

As your brand grows and you begin selling on Amazon, or get picked up by a major retailer, registered UPCs are required. Keep in mind that you can continue to use both: a SKU for internal use, and a UPC for external use. Here’s a quick comparison of a SKU, barcode, and UPC, and how they’re used.

Comparison of SKUs, UPCs, and Barcodes

We Do SKUs, UPCs, and Barcodes

As a full service, tech-enabled 3PL, ShipMonk uses barcodes at every stage in the ecommerce order fulfillment process to ensure that we’ve received the right products, that we know where they’re stored in our fulfillment warehouses, that we’re picking and packing the correct items in every order, and that we’re shipping them out the most economical way. We have the capability to generate barcodes for products, when necessary, and partner with every major shipping carrier to automatically generate accurate shipping barcodes. We also use barcodes to streamline the returns process. If you’re looking for a top-tier fulfillment partner, contact ShipMonk today and let us decode SKUs, UPCs, and barcodes for you!