When considering different branded boxes for your product packaging, the amount of options may cause choice paralysis.

Of all of the packaging printing options, digital printed packaging is currently the fastest growing segment, growing 13% year-over-year. In 2017 the industry had grown to $12.8B, and is on track to continue growing until 2022, reaching $22.4B in value.

So what’s behind the growth of digital printing?

Digital printing has quickly become the go-to printing method for packaging in many specific cases. Today we’ll dive into 5 different reasons you may want to consider this printing method for your branded boxes.

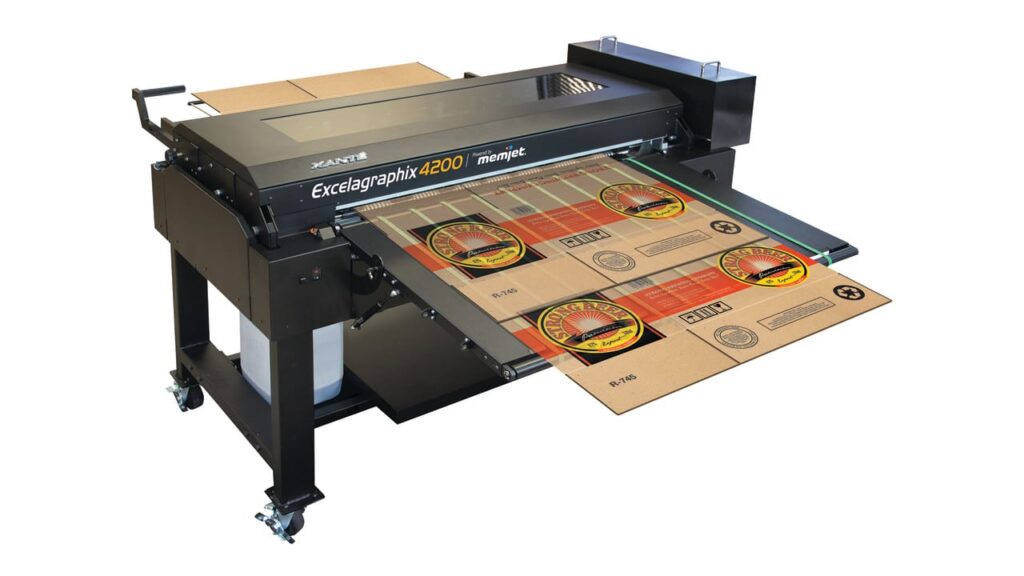

Digital printing – essentially a giant inkjet printer

First, we need to understand what digital printing is and how it’s different than other printing methods. Digital printing refers to method of printing on cardboard that is essentially a larger commercial version of your at home printer.

To get a better idea of how digital printing differs from other popular types of branded box printing, take a look at this quick outline:

- Digital printing prints line-by-line, just like an inkjet printer

- Flexo (flexographic) printing is like a stamp that rolls on a design, one color layer at a time

- Litho (lithographic) printing etches the design onto aluminum plates using a photographic process, then transfers the design onto the packaging

- Litho laminating prints a layer of paper is glued to the packaging

One major benefit of digital printing is the short prep time, but since it prints line by line, it does take longer. For that reason, it is more suited for comparatively small quantities of branded boxes, which can range between 10-2000 units.

5 reasons to choose digital printing

Due to the cost-efficiency for low batches and the flexibility of digital printing, there are a variety of reasons why digital printing is the best choice for printing your branded boxes. Here are five points to take into consideration.

1) Quick turnaround time

The only setup that a digital printer needs is to upload the print file. Other print methods require you to purchase plates and cutting dies to apply the design onto each box.

The result?

Digital printing is much faster and less expensive. The design process can easily be simplified by using online drag-and-drop design tools, such as the Arka Online Customizer for mailer and shipper boxes.

Bonus: since the print file is digital, it can easily be changed and edited at any moment, meaning that if your packaging requires frequent changes, then this won’t cost you a premium like flexo or litho printing will.

2) Flexible artwork options

Digital printing allows for a wide variety of printed artwork that you’d otherwise be limited to.

These are some features available to you when printing digitally:

- Color – With flexography you’re limited to seven colors (and the more colors, the more expensive). With digital printing, your artwork does not have to be restricted by the printing method.

- Gradients – Digital printing supports gradients in printing, which other common methods have trouble with.

- Photo-realistic imaging – Photo-realistic imaging can be used to demonstrate the product or people using it. can be used print photography on boxes, helpful if companies wanted to showcase an image of their product on the packaging itself.

The technology is in its infancy, and we’ve barely scratched the surface of its feature capabilities.

3) Can easily be changed to reflect seasonal/geographical nuances

Studies show that customized packaging has a positive impact on consumer behavior. As online shopping develops, the demand for branded box packaging is growing. Many brands are beginning to understand that the packaging of their boxes is also an opportunity to extend their branding and brand experience even further.

Thanks to the versatility of digital printing, businesses can test different packaging designs without incurring extra costs.

Some examples of branded box customization include:

- Adding festive elements to shipments around the holidays

- Adjusting the language and visuals for different geographical areas

- Catering to different social media platforms

4) The best printing method for Point-of-Purchase (POP) packaging

For brands that require Point-of-Purchase packaging that shows off their products in retail stores, digital printing is ideal.

Because Point-of-Purchase packaging is not required in as many copies as the product packaging itself, digital printing provides a balance of low-cost production and high results visuals.

Here’s why digital printing is best for Point-of-Purchase packaging:

- Vibrant, diverse image options

- This high-value printing is still cost-effective in low quantity orders

- Designs are quickly adapted and operational to reflect the needs of the local vendors, print types, box types, with relevant campaigns, product and ingredient information

5) Ideal for testing packaging designs

It’s important to test and iterate designs for your branded boxes before going to market.

For point of purchase displays, digital printing is the most cost-effective of the options to get your hands on a prototype quickly. You can test new designs without tooling and the manufacturer can use a CAD table to quickly cut out digitally printed samples for you to choose from.

It’s also a way to test different packaging options before investing in your own packaging equipment. This only makes sense when you know what kind of packaging you’ll want, and your runs are for thousands of boxes.

Digital printing is the future of branded boxes

We see that digital printing comes with many advantages when compared to traditional, large-scale printing options. The digital packaging printing industry continues to grow as consumer demand and expectations for packaging also grow. As a result, it’s clear that the flexible, short-run printing packaging options provided by digital printing will take the foreground to become one of the most demanded packaging printing options available.